You are now visiting store.ostoni.com, the section of our website dedicated to REFURBISHED PRODUCTS.

If you are looking for NEW PRODUCTS, please visit shop.ostoni.com.

If you are looking for NEW PRODUCTS IN OFFER, please visit deals.ostoni.com.

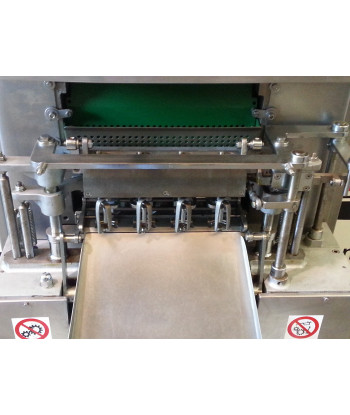

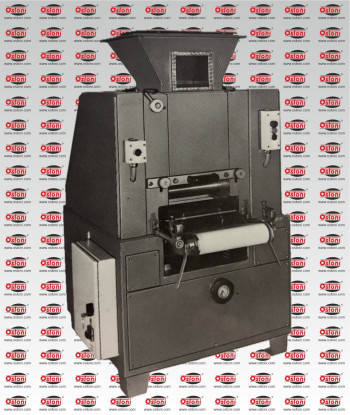

Toresani Pavan - Tortellini machine model MT265

Toresani Pavan

Tortellini machine model MT265

The MT265 model is a classical tortellini machine and has been designed for being used by pasta shops and small to medium sized wholesale producers. On this model, the filling group and moulds are removable for cleaning and sanitation. This machine is USDA approved for meat processing; sanitary materials are used throughout the product zone as well as on panels and framework. Sheet width mm. 265, hourly production Kgs. 50, the machine comes with a medium size tortellini shape # 4. Electrical equipment 220 / 400 V - 3 phases - 50 / 60 Hz., completely rebuilt, guaranteed 1 year, CE and USDA approved.

**********

How the Tortellini Machine Works for Classic Bologna Tortellini

1. Dough Sheet Feed and Preparation

Fresh pasta dough sheet (typically 5-6 mm thick) is fed into the machine via a conveyor belt or manually. The dough sheet must maintain constant width to ensure production uniformity.

2. Double Calibration

The tortellini machine uses a double dough sheet calibrator with stainless steel rollers. During this crucial phase:

- The dough sheet passes through the first group of calibrating cylinders that reduce thickness.

- The second calibrator brings the pasta to the optimal final thickness (about 0.6 mm).

- Precise regulation allows for accurate thickness control.

3. Pastella Cutting

The specific tortellini stamp cuts circular discs from the calibrated dough sheet:

- The alternating movement of the stamp cuts precise pasta portions.

- The discs have standardized diameter according to the desired format.

- Cutting frequency is adjustable for speed variation.

4. Filling Dosing

Simultaneously with cutting, dosing occurs:

- A system deposits a precise amount of filling at the center of each disc.

- Dosing is electronically controlled to maintain constant pasta/filling ratio.

- Quantity varies according to the specific format.

5. Half-Moon Folding

The disc with filling is folded in half:

- Mechanical devices press the edges to create the half-moon shape.

- Edge sealing occurs through calibrated pressure.

- This forms the tortellini base.

6. Final Shaping and "Hat Formation"

This is the distinctive phase for classic tortellini:

- Mechanical "little hands" grasp the half-moon extremities.

- They fold the tortellini around its central axis.

- They join and seal the two tips to create the characteristic "hat" shape.

- Pressure is calibrated to avoid breakage while ensuring seal integrity.

7. Ejection and Collection

The formed tortellini are:

- Ejected from the forming station.

- Collected on conveyor belts or trays.

- Optionally dusted with flour to prevent sticking.

The main difference compared to cappelletti machines lies in the final forming phase: while cappelletti are simply "pinched," tortellini require the characteristic circular folding that joins the extremities to create the traditional Bologna shape.

**********

Guaranteed 1 Year !!!

WHY TO BUY FROM A RESELLER ???

COME STRAIGHT TO THE SOURCE !!!

Feel free to call Ostoni in Italy for any info: Call +39 02663 05178.

WE HAVE THE WORLD'S LARGEST INVENTORY OF PASTA MACHINES AND DIES FOR THE PRODUCTION OF RAVIOLI, TORTELLINI, CAPPELLETTI, TORTELLONI, GNOCCHI, PELMENI, PIEROGI, VARENIKI AND A LOT OF OTHER PASTA SHAPES !!!

Data sheet

- 6 Production year

- 2009

- 8 Absorbed power

- kW 1.5

- 9 Sheet width

- mm. 265

- 10 Electrical system

- 220 / 400 V - 3 phases - 50 / 60 Hz.

- 11 Overall dimensions

- 800 x 900 x 1600 mm

- 12 Weight

- 360,00000 kg

- 14 Type_

- Tortellini machines

- 16 Condition

- Refurbished