You are now visiting store.ostoni.com, the section of our website dedicated to REFURBISHED PRODUCTS.

If you are looking for NEW PRODUCTS, please visit shop.ostoni.com.

If you are looking for NEW PRODUCTS IN OFFER, please visit deals.ostoni.com.

Dominioni Punto & Pasta - A250FD dual-output automatic sheeter-kneader

Dominioni Punto & Pasta

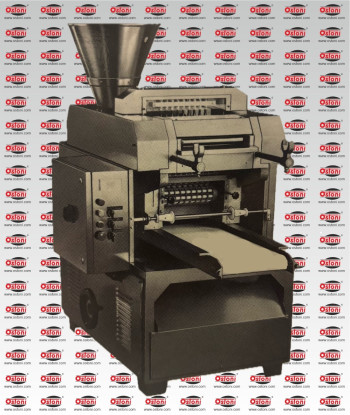

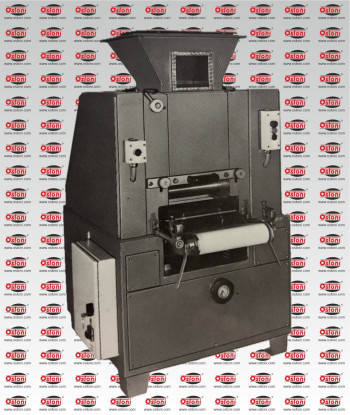

Dominioni Punto & Pasta A250FD Dual-Output Automatic Sheeter-Kneader

The A250FD automatic sheeter-kneader is designed to automate and speed up production processes in artisanal workshops or food industries.

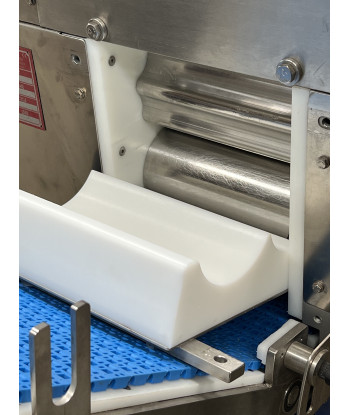

The processing of the two pasta sheets occurs automatically, perfectly solving mechanical and quality problems. By eliminating mechanical stress and unnecessary friction, this machine always guarantees the simultaneous production of two properly processed pasta sheets, cold-laminated and homogeneous, with a thickness of 5/7 mm each, depending on the raw materials.

Equipped with a double electrically tilting mixing hopper, the machine is capable of working with any type of flour or semolina, automatically producing pasta sheet rolls, or it can work in continuous cycle in combination with forming machines, specifically dual pasta sheet ravioli machines.

Built entirely in stainless steel, easy and convenient to clean.

Sheet width: 250 mm.

Electrical equipment 220 / 400 V - 3 phases - 50 / 60 Hz., completely rebuilt, guaranteed 1 year, CE and USDA approved.

**********

Automatic Sheeter-Kneader Operation with Dual Output

The dual-output automatic sheeter-kneader represents the evolution of the traditional machine, specifically designed to continuously feed filled pasta forming machines that require two simultaneous pasta sheets (such as dual-sheet ravioli machines).

Dough Preparation

The preparation system remains identical to the single version:

- Sheeter-kneaders with double hopper: Raw materials are loaded into the rear hopper for mixing (15 minutes), then transferred to the front hopper for feeding.

- Sheeter-kneaders with single hopper: The dough is prepared in a separate mixer and then transferred to the pasta sheet machine hopper.

Dual Lamination Process

The dough follows the same initial path but with a duplicated lamination system:

- Centralized feeding: The dough is pushed from the central hopper towards a distribution system that simultaneously feeds two parallel lamination lines.

- Double kneading group (one line for each sheet):

* Double push paddles: Two pairs of independent mechanical paddles push the dough towards their respective lamination groups.

* Double grooved rollers: Two parallel series of kneading cylinders (with "wave" cross-section) simultaneously work two portions of dough.

* Double smooth rollers: Two final pairs of smooth-surface cylinders complete the lamination in parallel.

- Synchronized control: The system is equipped with independent motorizations with inverters for each lamination line, ensuring perfect synchronization between the two sheets.

Specific Technical Features

Dough Distribution System:

- Central hopper with automatic distribution system.

- Automatic flow control to ensure uniform feeding to both lines.

- Level sensors to maintain constant feeding.

Double Lamination System:

- Two completely independent kneading-laminating groups.

- Double lateral shoulders for each group.

- Independent thickness adjustment for each sheet (typically 5-6mm).

- Loop control system to maintain optimal tension.

Synchronized Dual Output:

- Two sheets of identical width (250mm, 300mm, 320mm, 540mm or 600mm depending on the model).

- Simultaneous production with perfect temporal alignment.

- Speed control system for synchronization with downstream machines.

Operational Advantages

- Doubled productivity: Simultaneous production of two sheets (300-500 kg/hour depending on the model).

- Direct feeding: Perfectly synchronized for ravioli machines and dual-sheet forming machines.

- Guaranteed homogeneity: Uniform thickness and identical characteristics on both sheets.

- Energy efficiency: Optimized energy consumption compared to two separate machines.

- Quality control: Single control system for both production lines.

This configuration is particularly advantageous in medium and large pasta industries where continuous filled pasta production requires constant and synchronized feeding of two perfectly coordinated sheets.

**********

Guaranteed 1 Year !!!

WHY TO BUY FROM A RESELLER ???

COME STRAIGHT TO THE SOURCE !!!

Feel free to call Ostoni in Italy for any info:

Call +39 02663 05178.

WE HAVE THE WORLD'S LARGEST INVENTORY OF PASTA MACHINES AND DIES FOR THE PRODUCTION OF RAVIOLI, TORTELLINI, CAPPELLETTI, TORTELLONI, GNOCCHI, PELMENI, PIEROGI, VARENIKI AND A LOT OF OTHER PASTA SHAPES !!!

**********

All trademarks, logos and signs used in this website are property of the respective owners and are used for descriptive purposes only. Images, videos and product descriptions are indicative and not binding. Our company is not the company Dominioni Punto & Pasta, we are not associated with them and none of the objects offered on this website infringes patents owned by Dominioni Punto & Pasta. At the same time, our company ensures that all proposed objects referring to machines made or sold by Dominioni Punto & Pasta are perfectly compatible with the original ones and can be used on the machines of Dominioni Punto & Pasta.

Data sheet

- 6 Production year

- 2019

- 8 Absorbed power

- Kw 8

- 9 Sheet width

- mm. 250

- 10 Electrical system

- 220 / 400 V - 3 phases - 50 / 60 Hz.

- 11 Overall dimensions

- mm. 1710 x 1900 x 1650 (h)

- 12 Weight

- Kg. 2200

- 14 Type_

- Sheeter-kneaders

- 16 Condition

- Refurbished