You are now visiting store.ostoni.com, the section of our website dedicated to REFURBISHED PRODUCTS.

If you are looking for NEW PRODUCTS, please visit shop.ostoni.com.

If you are looking for NEW PRODUCTS IN OFFER, please visit deals.ostoni.com.

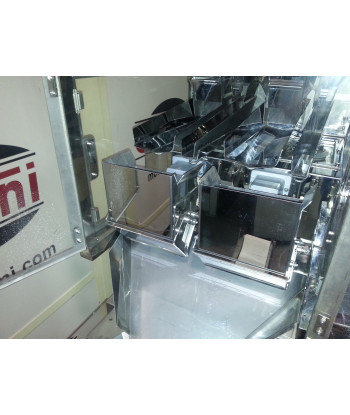

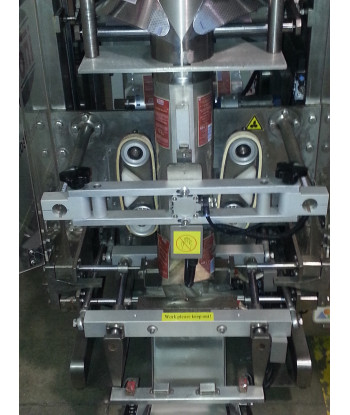

Pymar Group - Vertical packaging machine model Itepacp ITCB-500

Pymar Group

Vertical packaging machine model Itepacp ITCB-500

The Itepacp ITCB-500 is a vertical packaging machine with 2 weighters and it is suitable for medium production.

The machine has the following characteristics:

- Packaging speed: 5 - 60 bag / min.

- Film thickness: mm. 0,05 - 0,12

- Inner roller diameter: mm. 75

- Max. spool diameter: mm. 360

- Max. film width: mm. 420

- Bag size: Lenght mm. 50 - 300, width mm. 60 - 200

- Packaging materials: POPP/CPP, POPP/VMCPP, CPP/PE

- Shape of the bag: pillow, bottom bag, perforated bag

- Measurement range: ml 150 - 1300

- Air consumption: 350 l / min.

Electrical equipment 220 V - 1 phase - 50 / 60 Hz., completely rebuilt, guaranteed 1 year, CE and USDA approved.

**********

How a Vertical Bag Packaging Machine Works

General Machine Structure

The machine develops vertically with different functional sections:

- Upper part: weighing and dosing system

- Central part: bag formation from plastic film

- Lower part: sealing and final cutting

Detailed Operating Process

1. Product Loading

- The pasta is loaded into a feeding hopper in the upper part of the machine

- A gentle agitator system keeps the product moving to avoid compaction

- The product descends by gravity toward the weighing scales

2. Multihead Weighing System

- The machine typically uses 10-14 independent electronic scales (multihead weighers)

- Each scale receives a quantity of product and weighs with gram precision

- The central computer calculates which combination of scales reaches exactly the target weight

- The selected scales simultaneously discharge the product toward the drop tube

3. Bag Formation

- A roll of plastic film (usually polyethylene or laminate) unwinds from the top

- The film passes through a "forming tube" that gives it the tubular shape

- A longitudinal sealer creates the vertical seam of the bag as the film descends

- By changing the film advance length and the set weight, bags of different weights can be created using the same forming tube

4. Packaging Process

- The machine automatically forms the bottom of the bag through a cross seal

- The weighed product descends through the drop tube and fills the bag

- During the fall, an air blowing system can help distribute the product evenly

5. Final Sealing and Cutting

- Once filled, the bag is sealed at the top with a second cross seal

- Simultaneously with the top sealing, it is cut to separate it from the continuous film

- The finished bag falls onto a conveyor belt or collection container

Control and Safety Systems

Automatic Controls:

- Weight control: verifies that each package meets tolerances

- Seal control: sensors verify the quality of seals

- Product presence control: optical sensors verify filling

Safety Systems:

- Metal detectors to identify any contamination

- Automatic ejection systems for defective packages

- Emergency stops and operator protection systems

Adjustable Parameters

The operator can set:

- Target weight of packages

- Bag length

- Temperature and time of seals

- Production speed (typically 30-120 packages/minute)

- Acceptable weight tolerances

Specific Features for Filled Pasta

For this type of delicate product, the machines feature:

- Gentle drop systems to avoid breaking ravioli/tortellini

- Temperature control to preserve freshness

- Modified atmosphere packaging (MAP) capability to increase shelf-life

- Easily washable surfaces and components for food hygiene

This type of machine ensures high productivity, weighing precision, and consistent packaging quality, essential for fresh products like filled pasta.

**********

Guaranteed 1 Year !!!

WHY TO BUY FROM A RESELLER ???

COME STRAIGHT TO THE SOURCE !!!

Feel free to call Ostoni in Italy for any info: Call +39 02663 05178.

WE HAVE THE WORLD'S LARGEST INVENTORY OF PASTA MACHINES AND DIES FOR THE PRODUCTION OF RAVIOLI, TORTELLINI, CAPPELLETTI, TORTELLONI, GNOCCHI, PELMENI, PIEROGI, VARENIKI AND A LOT OF OTHER PASTA SHAPES !!!

Data sheet

- 6 Production year

- 2012

- 8 Absorbed power

- Kw 3

- 10 Electrical system

- 220 V - 1 phase - 50 / 60 Hz.

- 11 Overall dimensions

- 3500 x 960 x 3000 mm

- 12 Weight

- 350,00000 kg

- 14 Type_

- Vertical packaging machines