You are now visiting store.ostoni.com, the section of our website dedicated to REFURBISHED PRODUCTS.

If you are looking for NEW PRODUCTS, please visit shop.ostoni.com.

If you are looking for NEW PRODUCTS IN OFFER, please visit deals.ostoni.com.

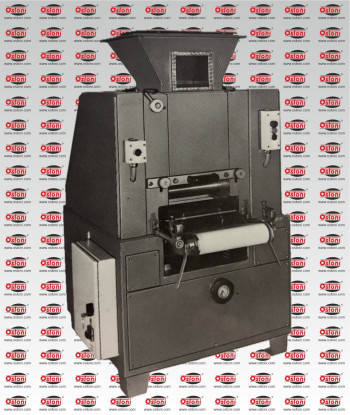

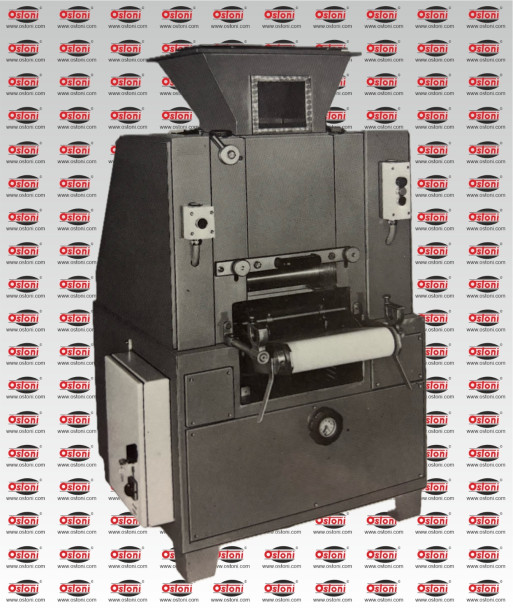

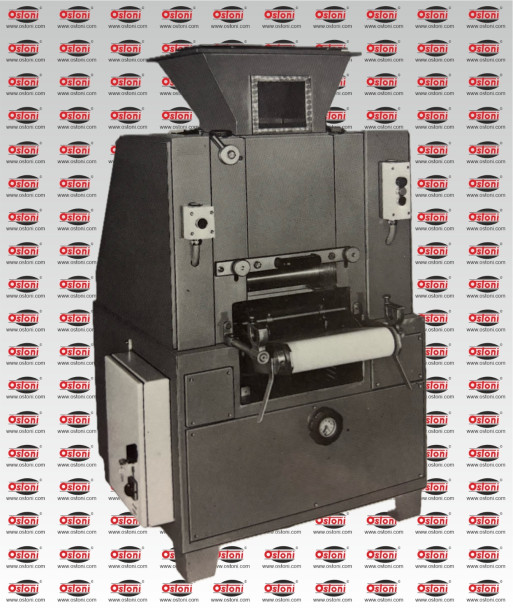

Toresani Pavan - Automatic sheeter-kneader model SFA300

Toresani Pavan

Automatic sheeter kneader Toresani Pavan model SFA300

Machine to automate, renew and improve the safety of the manufacturing process; suitable for medium-large shops, laboratories, food industries, etc. The dough sheet is processed automatically, thus solving any mechanical and quality issues. The machine removes the useless mechanical stress and friction and, depending on the raw materials, a cold-laminated and homogenous, 5-7 mm thick dough-sheet is obtained. The machine can process any type of flour or durum wheat flour and produce dough-sheet rolls or it can also be combined with other machines such as ravioli, cappelletti and tortellini makers, automatic cutters, etc. The SFA300 can be easily cleaned and produces Kg. 250 / hour of sheet width mm. 300.

Electrical equipment 220 / 400 V - 3 phases - 50 / 60 Hz., completely rebuilt, guaranteed 1 year, CE and USDA approved.

**********

Operation of the Sheeter Kneader

Automatic pasta sheeters (or automatic pasta sheet machines) are industrial machines designed to transform dough into laminated pasta sheets of uniform thickness. Here's how they work in general:

Dough Preparation

Automatic cylinders with double hopper:

- Raw materials (flour, eggs, water, etc.) are loaded into the rear hopper

- After approximately 15 minutes of kneading, the completed dough is transferred to the front hopper for feeding the lamination system

Automatic cylinders with single bowl:

- The dough is prepared separately in a dedicated mixer

- Once ready, it is transferred to the pasta sheeter machine hopper

Lamination Process

The dough follows a path through different processing stages:

1. Feeding from the hopper: The dough is pushed from the hopper toward the kneading unit through a controlled feeding system.

2. Kneading unit (typical sequence):

- Push paddles: A pair of mechanical paddles pushes the dough downward, ensuring constant feeding

- Grooved rollers: One or two pairs of grooved cylinders (with the characteristic "wave-like" section) that begin to work and compact the dough

- Smooth rollers: A final pair of smooth-surface cylinders that completes the lamination

3. Final result: The process produces a laminated pasta sheet with uniform thickness of approximately mm. 6, ready for subsequent processing.

Output Systems

Standard single output:

- The sheet can be sent directly to downstream forming machines (ravioli makers, cappelletti makers, tortellini makers, pasta cutters)

- Or it can be wrapped on rolling pins for manual feeding of other machines

Double output:

- Specialized versions produce two sheets simultaneously

- Particularly useful for automatically feeding double-sheet ravioli makers

This system ensures continuous and standardized production of pasta sheets, optimizing processing times and maintaining consistent quality of the final product.

**********

Guaranteed 1 Year !!!

WHY TO BUY FROM A RESELLER ???

COME STRAIGHT TO THE SOURCE !!!

Feel free to call Ostoni in Italy for any info:

Call +39 02663 05178.

WE HAVE THE WORLD'S LARGEST INVENTORY OF PASTA MACHINES AND DIES FOR THE PRODUCTION OF RAVIOLI, TORTELLINI, CAPPELLETTI, TORTELLONI, GNOCCHI, PELMENI, PIEROGI, VARENIKI AND A LOT OF OTHER PASTA SHAPES !!!

Data sheet

- 6 Production year

- 2001

- 8 Absorbed power

- kW 6

- 9 Sheet width

- mm. 300

- 10 Electrical system

- 220 / 400 V - 3 phases - 50 / 60 Hz.

- 11 Overall dimensions

- mm. 910 x 1070 x 1540 (h)

- 12 Weight

- 600,00000 kg

- 14 Type_

- Sheeter-kneaders