You are now visiting store.ostoni.com, the section of our website dedicated to REFURBISHED PRODUCTS.

If you are looking for NEW PRODUCTS, please visit shop.ostoni.com.

If you are looking for NEW PRODUCTS IN OFFER, please visit deals.ostoni.com.

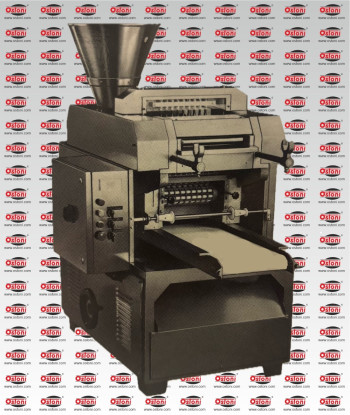

Toresani Pavan - Automatic cappelletti and ravioli machine model MR540

Toresani Pavan

Automatic cappelletti and ravioli machine model MR540

The Toresani Pavan MR540 ravioli machine can be used for the production of ravioli and shaped pasta in various formats. It is suitable for operation in continuous industrial lines and can be used in combination with automatic cylinders and presses. The four components groups of the machine (calibrator, filling forwarder, moulder and scrap recovery unit) are independent of each other. This modular construction system makes the machine easy to clean and maintain and, most important of all, means that it can be adapted and modified in line with specific customer requirements. Among the main technical specifications of the machine, we should mention the mm. 540 width double calibrator, the continuous filling forwarder and the easily changeable moulds. These details together with the solidity of the construction, mean that the Toresani Pavan MR540 is a reliable, quality product, fully in line with the strictest international hygiene regulations.

The machine comes with two new dies: one for "pinzati" (cappelletti or tortelloni) and one for folded ravioli. It is possible to buy additional dies for getting more shapes. Completely rebuilt, electrical equipment 220 / 400 V - 3 phases - 50 / 60 Hz., guaranteed 1 year, CE and USDA approved.

**********

How a Ravioli-Cappelletti Machine Works

Ravioli-cappelletti machines, also called single-sheet forming machines, represent an advanced technological solution for the industrial production of stuffed pasta using a single pasta sheet. These versatile machines allow the production of different types of products: ravioli closed on three sides (with square or half-moon formats), "pinched" cappelletti and tortelloni, as well as other stuffed pasta formats such as sachets, bundles, and candies.

General Operating Principle

The processing of ravioli-cappelletti machines is based on a continuous production cycle that transforms a fresh pasta sheet into finished products through several automated sequential phases. The distinctive characteristic of these machines is the use of interchangeable molds that allow obtaining different shapes and sizes of stuffed pasta from the same production line.

Production Process Phases

1. Preparation and Calibration of the Sheet

The process begins with feeding the fresh pasta sheet, which can come from a pasta press or an automatic sheeter-kneader. The incoming sheet generally has a thickness of about 6 millimeters.

The sheet then passes through a calibrating unit, which can be single or double type depending on the machine model. This system of laminating cylinders progressively reduces the pasta thickness until it reaches the optimal value of about 0.6 millimeters. Calibration is fundamental to ensure uniformity in the final product and allow correct sealing.

2. Cutting and Formation of the Pastella

Once calibrated, the sheet enters the forming station where the interchangeable mold performs the cutting of precise portions of pasta, called in Italian "pastella". The mold, operated by a mechanical system with alternating movement, cuts the sheet according to the shape and dimensions desired for the specific product.

The cutting frequency (beats per minute) is adjustable and varies based on the format of the product to be made. Larger formats require longer cycle times to allow proper filling and sealing.

3. Filling Dosing

Simultaneously with cutting, a precise amount of filling is deposited inside each pastella. The filling dosing system can be implemented through different technologies:

• Screw system: uses an endless screw to push the filling toward the dosing nozzle

• Lobe pump: used for denser fillings or those with pieces, guarantees precise volumetric dosing

• Vacuum pump: ideal for delicate fillings that could be damaged by mechanical pressure

The amount of filling is accurately adjustable through dedicated controls, allowing to maintain constant the pasta/filling ratio according to product specifications.

4. Folding and Sealing

After filling dosing, the pastella is folded on itself and then manipulated according to the desired shape. Sealing occurs through pairs of rotating cylinders called in Italian "godroni", which exert pressure on the pasta edges to create an airtight closure.

The godroni are designed with reliefs that create the edge that guarantees safe sealing and prevents filling leakage during cooking.

5. Pinching (only for cappelletti and tortelloni)

For the production of cappelletti and tortelloni, after initial sealing an additional pinching operation is performed. This phase, absent in ravioli production, consists of mechanical manipulation of the pasta edges to create the characteristic "hat" shape.

Pinching is accomplished through specific mechanical devices (the so-called in Italian "manine") that fold and shape the product to its distinctive final form.

Technical Characteristics and Versatility

Interchangeable Molds

The main characteristic of modern ravioli-cappelletti machines is the ease of mold changing. The molds are designed to be quickly replaced, allowing switching from one product format to another in minimal time. Each mold determines:

• Product shape (square, round, rectangular)

• Final dimensions

• Type of border

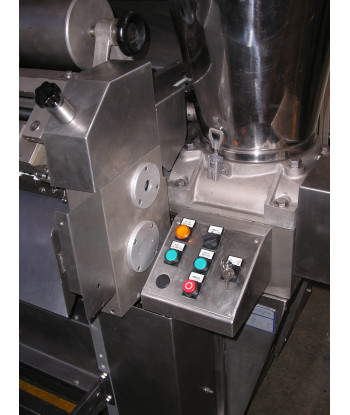

Controls and Adjustments

The machines are equipped with numerous adjustable parameters:

• Sheet thickness: through the calibrating unit

• Amount of filling: through the dosing system controls

• Production speed: by adjusting the frequency of mold beats

Materials and Hygiene

All parts in contact with food are made of AISI 304 stainless steel, easily removable to ensure accurate cleaning and compliance with food hygiene standards. This aspect is fundamental for industrial production and compliance with HACCP regulations.

Accessories and Completions

The machines can be equipped with auxiliary systems to optimize the production process:

• Waste cutting system: for automatic recovery of pasta scraps

• Conveyor belts: for finished product handling

• Flouring systems: to prevent product adhesion

• Quality control devices: to verify weight and shape of products

The flexibility of these machines makes them ideal for producers who need to frequently vary product formats while maintaining high quality and production standards.

**********

Guaranteed 1 Year !!!

WHY TO BUY FROM A RESELLER ??? COME STRAIGHT TO THE SOURCE !!!

Feel free to call Ostoni in Italy for any info: Call +39 02663 05178.

WE HAVE THE WORLD'S LARGEST INVENTORY OF PASTA MACHINES AND DIES FOR THE PRODUCTION OF RAVIOLI, TORTELLINI, CAPPELLETTI, TORTELLONI, GNOCCHI, PELMENI, PIEROGI, VARENIKI AND A LOT OF OTHER PASTA SHAPES !!!

Data sheet

- 6 Production year

- 2007

- 8 Absorbed power

- kW 6

- 9 Sheet width

- mm. 540

- 10 Electrical system

- 220 / 400 V - 3 phases - 50 / 60 Hz.

- 11 Overall dimensions

- 1450 x 1650 x 1530 mm

- 12 Weight

- 1200,00000 kg

- 14 Type_

- Cappelletti machines

- 16 Condition

- Refurbished