You are now visiting store.ostoni.com, the section of our website dedicated to REFURBISHED PRODUCTS.

If you are looking for NEW PRODUCTS, please visit shop.ostoni.com.

If you are looking for NEW PRODUCTS IN OFFER, please visit deals.ostoni.com.

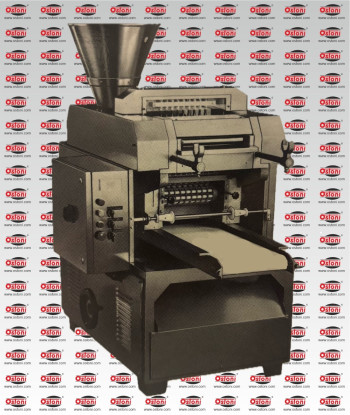

Italgi - Troffie machine model F10

Italgi

Troffie machine model F10

Forming machine for typical regional pasta shapes, such as troffie, cavatelli, olive leaves, etc.; by changing the mould it is possible to obtain other different pasta shapes, up to a maximum of 10 pieces simultaneously. Simply using the machine adjustments (belt speed, knife speed and roller speed) you can vary the size of the product, even while the machine is in production..

Electrical equipment 220 / 400 V - 3 phases - 50 / 60 Hz., completely rebuilt, guaranteed 1 year, CE and USDA approved.

**********

How a Trofie Machine Works

A trofie machine operates through a sequence of well-defined mechanized phases, transforming raw dough into the desired pasta shape, replicating traditional human movements.

The process begins with the preparation of the dough, typically composed of durum wheat semolina and water. The consistency of the dough is of fundamental importance: it must be firm, smooth, and non-sticky, often described as similar to "rice grains" or having a "hardish" consistency.

The operation of a trofie machine is structured into the following key steps:

a) Feeding and Filament Formation: The dough can be introduced into the machine's hopper and then channeled by pressure to obtain continuous pasta filaments approximately 10 mm in diameter. Alternatively, the dough can come directly from a die of a press that simultaneously produces multiple continuous pasta filaments, each approximately 10 mm in diameter.

b) Filament Cutting: After the filaments are formed, a knife intervenes with adjustable speed to cut these filaments to the desired length.

c) Passage Under the Mold: The cut pasta pieces then pass under a mold. This mold is positioned to leave a determined and adjustable height relative to the conveyor belt.

d) Twisting and Final Shape: The forced passage of the pasta under the mold, in combination with the movement of a conveyor belt, twists the pasta and gives it its characteristic spiral shape. This mechanism replicates the manual movement of "rubbing" or "twisting" the dough.

Modern machines are equipped with controls that allow for varying the dimensions of the final product (width, thickness, and length) by adjusting the speed parameters of the belt, knife, and roller. This adjustment can even be made "while the machine is in production" , minimizing downtime. The versatility of these machines is further expanded by the ability to produce "different types of traditional dragged pasta such as trofie, cavatelli, olive leaves, etc." simply by changing the "mounted mold" or the "forming unit".

**********

Guaranteed 1 Year !!!

WHY TO BUY FROM A RESELLER ???

COME STRAIGHT TO THE SOURCE !!!

Feel free to call Ostoni in Italy for any info:

Call +39 02663 05178.

WE HAVE THE WORLD'S LARGEST INVENTORY OF PASTA MACHINES AND DIES FOR THE PRODUCTION OF RAVIOLI, TORTELLINI, CAPPELLETTI, TORTELLONI, GNOCCHI, PELMENI, PIEROGI, VARENIKI AND A LOT OF OTHER PASTA SHAPES !!!

Semolina, water and salt: three simple ingredients to create the delicious troffie, an historical pasta shape, now known and loved all over the world. This typical dish of Liguria is the result of female creativity, which handcrafted it for family consumption or sale. An ancient tradition that made the troffie a symbol of Ligurian cuisine; troffie with pesto ... who does not know this dish ?

A curiosity: is it called trofie, or troffie ? A true Genoese says troffie, the Italians say it with only one "F" !

Data sheet

- 6 Production year

- 2012

- 7 Hourly output

- Kgs. 50

- 8 Absorbed power

- kW 1

- 10 Electrical system

- 220 / 400 V - 3 phases - 50 / 60 Hz.

- 11 Overall dimensions

- cm. 87 x 90 x 156 (h)

- 12 Weight

- 110 Kg.

- 14 Type_

- Troffie machines

- 16 Condition

- Refurbished