You are now visiting store.ostoni.com, the section of our website dedicated to REFURBISHED PRODUCTS.

If you are looking for NEW PRODUCTS, please visit shop.ostoni.com.

If you are looking for NEW PRODUCTS IN OFFER, please visit deals.ostoni.com.

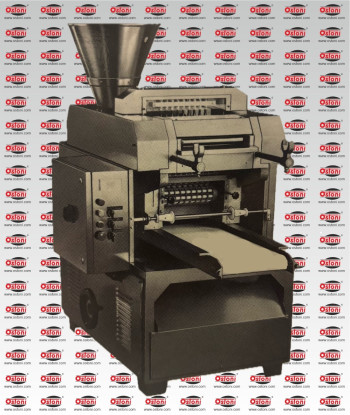

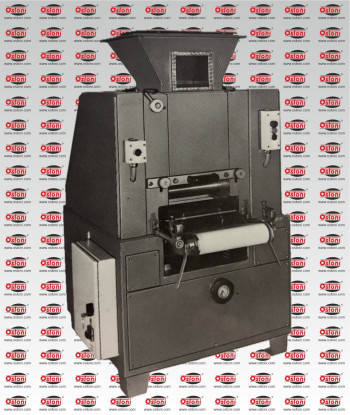

Dominioni Punto & Pasta - Gnocchi cooker model IG25

Dominioni Punto & Pasta

Gnocchi cooker model IG25

The boiler can knead and cook “gnocchi” (potato dumplings) and also mix and cook creams. Pan capacity: 25 litres.

It is composed as follows:

- stainless steel tilting tank with oil gap for homogenous and even cooking, to prevent the mix from sticking onto the surface;

- reel unit with sun-and-planet rotation;

- gas burner.

Electrical equipment 220 / 400 V - 3 phases - 50 / 60 Hz., completely rebuilt, guaranteed 1 year, CE and USDA approved.

**********

How a Gnocchi Kettle Works

The gnocchi kettle is a professional machine for the hot preparation of gnocchi dough. Through controlled heating and the planetary movement of the agitator, it allows the amalgamation of potatoes and flour to obtain a homogeneous dough with the right consistency.

Basic Ingredients

For Classic Potato Gnocchi

- Potatoes: 1 kg of boiled and mashed potatoes (still warm)

- Type 00 Flour: 200-300g (depending on potato moisture content)

- Egg: 1 whole egg (optional)

- Salt: 1 teaspoon

- Nutmeg: A pinch (optional)

Preparation Process

1. Ingredient Preparation

- Potatoes: Boil potatoes with skin, peel while still hot and mash with a potato masher

- Flour: Sift the flour to avoid lumps

- Temperature: Potatoes must still be warm (not cold) for better amalgamation

2. Loading into the Kettle

- Insert the warm mashed potatoes into the kettle tank

- Add salt and mix briefly

- If used, add the beaten egg

3. Starting the Mixing Process

- Turn on the agitator with planetary movement at low speed

- Begin adding flour gradually, a little at a time

- The rotary movement of the agitator amalgamates the ingredients uniformly

4. Controlled Heating

- Turn on the burner at very low flame

- Gentle heat helps amalgamation and slightly dries the dough if too moist

- Temperature: Maintain around 40-50°C (never exceed 60°C to avoid cooking the egg)

5. Consistency Control

- Processing time: 8-12 minutes of mixing

- Final consistency: The dough must be soft, elastic but not sticky

- Adjustments: Add flour if too soft, or a little water if too dry

6. End of Process

- Turn off heating

- Continue mixing for another 2-3 minutes to homogenize

- Stop the agitator when the dough has reached the desired consistency

Advantages of the Hot System

- Perfect Amalgamation

- Uniform heat: Gentle heating favors ingredient amalgamation

- Planetary movement: The agitator ensures homogeneous mixing without overworking

- Moisture control: Heat allows regulation of dough consistency

Production Efficiency

- Reduced times: Process completed in 10-15 total minutes

- Quantity: Possibility to prepare large quantities of dough uniformly

- Consistent quality: Each batch has the same characteristics

Dough Variations

Ricotta Gnocchi

- Base: 500g fresh ricotta, 200g flour, 1 egg, salt

- Process: Cold or room temperature mixing

- Time: 5-8 minutes of processing

Semolina Gnocchi

- Base: 250g semolina, 1 liter milk, butter, parmesan, eggs

- Process: Gradual heating until obtaining a thick cream

- Time: 15-20 minutes with continuous heating

Spinach Gnocchi

- Base: 800g potatoes, 200g boiled and squeezed spinach, 250g flour

- Process: Like classic gnocchi, adding spinach to potatoes

- Time: 10-12 minutes

Quality Control

- Consistency Test

- Tactile test: Dough should not stick to hands

- Elasticity: Must be elastic but not rubbery

- Moisture: Should be neither too dry nor sticky

Visual Indicators

- Uniform color: Dough must have homogeneous color

- Smooth surface: Absence of lumps or non-amalgamated parts

- Consistency: Must easily detach from tank walls

Using the Dough

- Immediate Shaping

By machine: Transfer the dough into the hopper of the gnocchi machine

By hand:

- Transfer dough to a floured surface

- Divide into portions and form cylinders

- Cut and shape gnocchi as desired

Storage

- Short term: Cover with damp cloth for max 2 hours

- Refrigeration: In refrigerator for maximum 24 hours

- Freezing: Possible after shaping the gnocchi

Cleaning and Maintenance

After Each Use

- Clean the tank immediately while still warm to facilitate residue removal

- Disassemble and thoroughly clean the agitator

- Use hot water and neutral detergent

- Completely dry all parts

Periodic Maintenance

- Check agitator blade wear

- Verify proper functioning of heating system

- Lubricate movement mechanisms according to manufacturer's instructions

The kettle transforms gnocchi dough preparation from a manual and laborious process to an automated procedure, ensuring professional results with consistent quality and optimized production times.

**********

Guaranteed 1 Year !!!

WHY TO BUY FROM A RESELLER ???

COME STRAIGHT TO THE SOURCE !!!

Feel free to call Ostoni in Italy for any info:

Call +39 02663 05178.

WE HAVE THE WORLD'S LARGEST INVENTORY OF PASTA MACHINES AND DIES FOR THE PRODUCTION OF RAVIOLI, TORTELLINI, CAPPELLETTI, TORTELLONI, GNOCCHI, PELMENI, PIEROGI, VARENIKI AND A LOT OF OTHER PASTA SHAPES !!!

Data sheet

- 6 Production year

- 2006

- 8 Absorbed power

- kW 1

- 10 Electrical system

- 220 / 400 V - 3 phases - 50 / 60 Hz.

- 11 Overall dimensions

- 650 x 640 x 1120 mm

- 12 Weight

- 118,00000 kg

- 14 Type_

- Gnocchi kettles

- 16 Condition

- Refurbished