You are now visiting store.ostoni.com, the section of our website dedicated to REFURBISHED PRODUCTS.

If you are looking for NEW PRODUCTS, please visit shop.ostoni.com.

If you are looking for NEW PRODUCTS IN OFFER, please visit deals.ostoni.com.

Italpast - Nests machine model N540

Italpast

Nests machine model N540

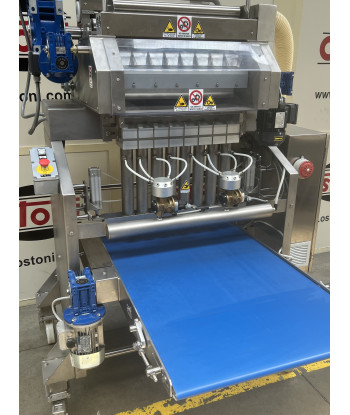

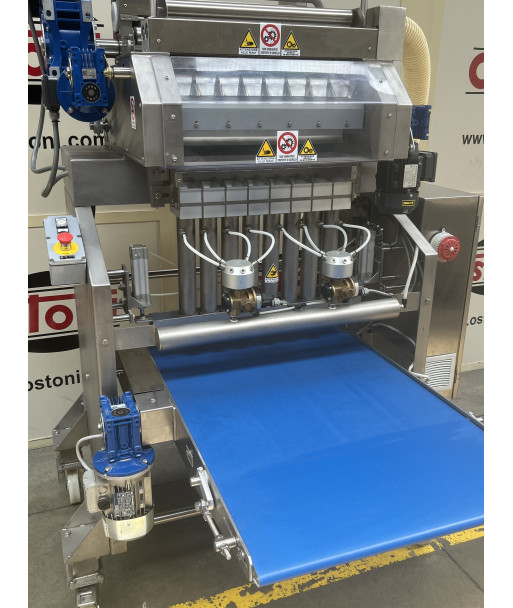

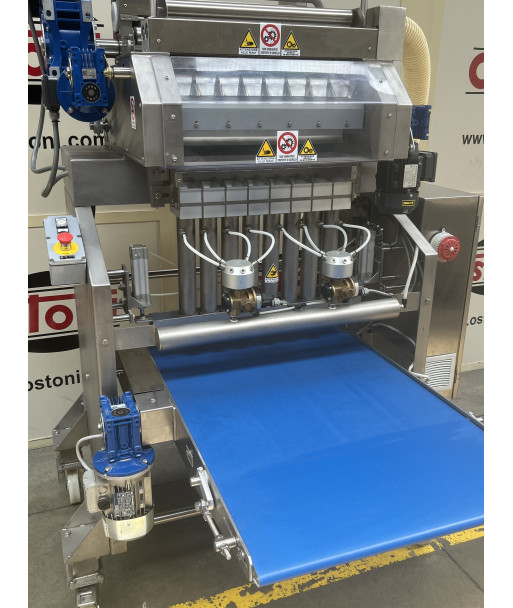

Machine suitable for the production of nests obtained from sheet width mm. 540. Framework, calibrating group, interchangeable cutting groups, all made in AISI 304 stainless steel.

The forming of the nests takes place through a pneumatic system, with 8 stainless steel forming tubes, diameter mm. 50, length mm. 430. The maximum cutting length is mm. 400, the indicative diameter of the nest is mm. 60, with variable weight according to the width and length of the cut and according to the thickness of the sheet.

The cutting length is adjustable via a speed motovariator; the electrical control panel is equipped with PLC Siemens programming keyboard. The machine is equipped with 3 interchangeable molds with different widths: tagliolini mm. 2.5, tagliatelle mm. 5 and pappardelle mm. 12.

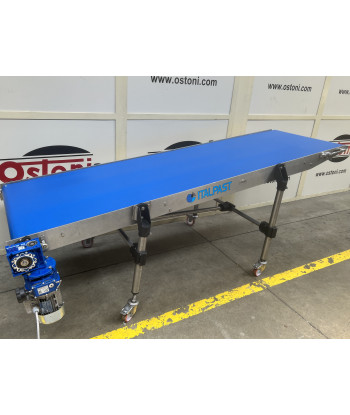

The machine is supplied with a connecting belt, width mm. 800, length mm. 2600 and heights mm. 670 and 1000. Electrical equipment 220 / 400 V - 3 phases - 50 / 60 Hz., completely rebuilt, guaranteed 1 year, CE and USDA approved.

**********

How a Nests Pasta Machine Works

General Description

The nests machine is an automatic industrial machine designed for the production of fresh pasta nests obtained from laminated sheets or extruded sheets. This machine is particularly suitable for the production of tagliatelle, tagliolini, pappardelle, spaghetti alla chitarra and other long pasta formats in nest form, intended for fresh sale, freezing or drying.

Sheet Processing

Sheet Feeding

The sheet (laminated or extruded), coming from an automatic cylinder or from a press, is fed to the nests machine through a connecting conveyor belt. With a special guide system, the sheet is guided and maintained under constant tension to ensure process uniformity.

Calibration and Lamination Group

Before cutting, the sheet passes through the calibration group:

- Calibrating rollers: A pair of thickness-adjustable laminating rollers, controlled by inverter, that standardize the sheet thickness.

- Automatic thickness control: The system ensures uniform thickness across the entire sheet width.

- Fine adjustment: The motovariator allows precise adjustment of the feed speed.

Cutting System

The calibrated sheet is then processed by the cutting group: the machine can accommodate interchangeable dies with different cutting widths.

- Cutting knife: A variable-speed cutting system that determines the final length of the pasta strips.

- Length adjustment: The cutting length is adjustable up to a maximum of approximately 400mm via motovariator.

Nest Formation

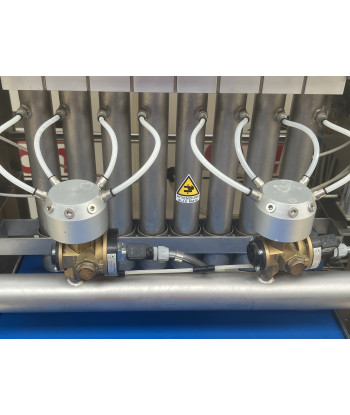

The most characteristic process of the nests machine occurs in the nest formation section:

- Pneumatic system: An automatic pneumatic system manages nest formation, through a blast of compressed air that is introduced inside the forming tubes, for an adjustable period of time.

- The stainless steel forming tubes have a diameter of 50mm and length of 430mm.

- Winding process: The cut pasta strips settle on the bottom of the tube and are then hit by an air blast, creating the characteristic nest shape.

- Nest diameter: The indicative diameter of the resulting nest is approximately 60mm.

Automatic Depositing

Once formed, the nests are automatically deposited:

- Ejection system: The nests are released from the forming tubes through a pneumatic system.

- Depositing on trays: The nests are automatically deposited on drying trays.

OR

- Depositing on conveyor belt.

Main Possible Adjustments

- Sheet thickness: Adjustable through calibrating rollers.

- Cutting speed: Controlled by motovariator to determine strip length.

- Duration of compressed air blast for nest formation: Managed by the pneumatic system to optimize nest shape.

- Synchronization: All movements are synchronized by the PLC to ensure a smooth process.

Versatility

- Multiple formats: Possibility to produce different types of long pasta simply by changing the die.

- Adaptability: Quick adjustments for different dough types and sheet thicknesses.

- Continuous production: Automated system that does not require continuous manual intervention.

- Facilitated maintenance: Easily accessible components for cleaning and maintenance.

This machine represents a complete solution for automatic production of pasta nests, integrating in a single system all phases from sheet calibration to automatic depositing of nests on drying trays, or on conveyor belt.

**********

Guaranteed 1 Year !!!

WHY TO BUY FROM A RESELLER ???

COME STRAIGHT TO THE SOURCE !!!

Feel free to call Ostoni in Italy for any info: Call +39 02663 05178.

WE HAVE THE WORLD'S LARGEST INVENTORY OF PASTA MACHINES AND DIES FOR THE PRODUCTION OF RAVIOLI, TORTELLINI, CAPPELLETTI, TORTELLONI, GNOCCHI, PELMENI, PIEROGI, VARENIKI AND A LOT OF OTHER PASTA SHAPES !!!

**********

All trademarks, logos and signs used in this website are property of the respective owners and are used for descriptive purposes only. Images, videos and product descriptions are indicative and not binding. Our company is not the company Italpast we are not associated with them and none of the objects offered on this website infringes patents owned by Italpast At the same time, our company ensures that all proposed objects referring to machines made or sold by Italpast are perfectly compatible with the original ones and can be used on the machines of Italpast.

Data sheet

- 6 Production year

- 2021

- 8 Absorbed power

- kW 4

- 9 Sheet width

- mm. 540

- 10 Electrical system

- 220 / 400 V - 3 phases - 50 / 60 Hz.

- 11 Overall dimensions

- mm. 1800 x 1995 x 2220 (h)

- 12 Weight

- 400 kg

- 14 Type_

- Automatic nests cutters